Cova-Wall® Cavity Cladding is a lightweight Exterior Insulation Finishing System that gives you the freedom of design that no other cladding material can offer as it consists of an enhanced water management system. Your possibilities in colors, details, form and texture are endless. Cova-Wall® provides your building with a protective blanket of continuous insulation, and enables excellent strength-to-weight ratios. As a result; your building will not only be beautiful, but well-insulated, cost-effective and long lasting.

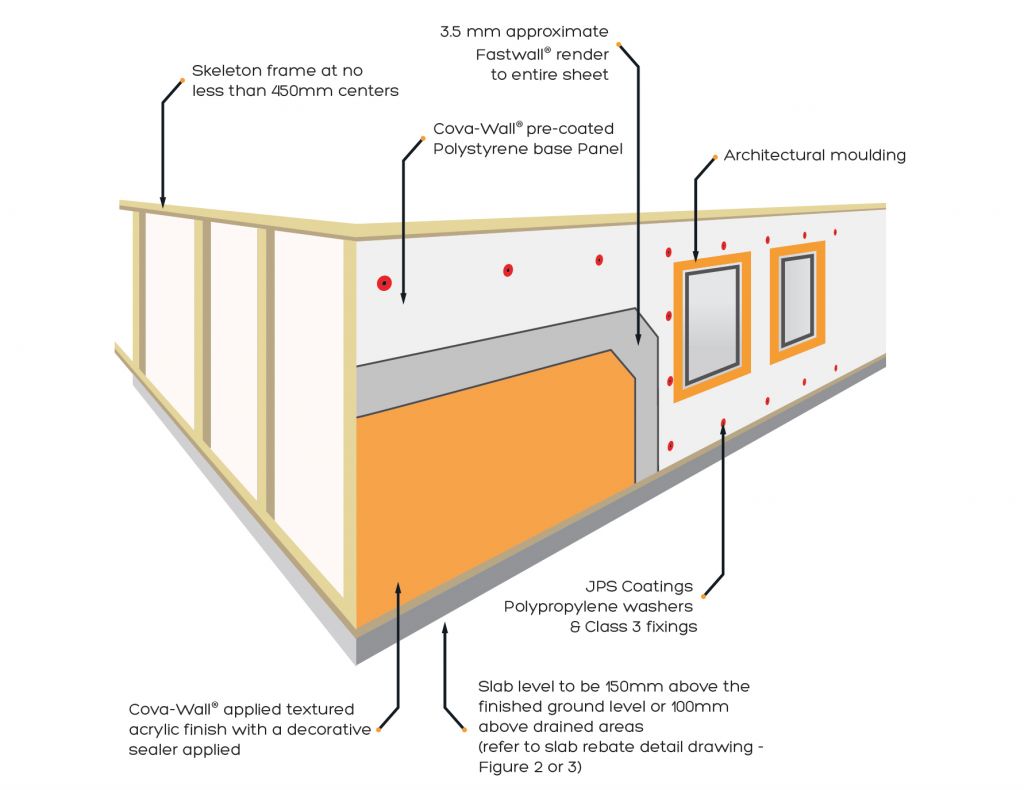

Cova-Wall® Cavity Cladding System is a reinforced lightweight insulated cladding system for use on exterior walls of buildings. Commonly referred to as Exterior Insulation and Finishing Systems (EIFS); it is made from “M” grade expanded polystyrene (EPS) moulded Panels anchored to the wall frame having “H” grade EPS Battens in between. This creates an air cavity between the Breathable Wall Wrap (sarking) and back face of the EPS Panel which allows for enhanced drainage of water and thus avoids any damage to the internal wall frame. The Panels are coated and reinforced with an exterior coating system to give an exterior wall a durable structure and weatherproofing properties.

Cova-Wall® Cavity EIFS Cladding System Attributes

- Structure Stability

- Thermal Insulation

- Weatherproofing

- Enhanced Water Management System

- Decorative Exterior Wall Finish

A proven choice for all climates and substrates, Cova-Wall® Panels are advanced wall cladding assemblies engineered for performance, design freedom, and durability. Whatever your project, Cova-Wall® provides the best value in an integrated wall cladding of unequaled aesthetic and technological elegance that is user friendly to install and cost-effective. Cova-Wall® with its advanced 100% acrylic chemistry looks new longer. They resist fading, peeling, cracking, dirt pick-up, mildew, mould and other biological growth. They are easily cleaned by low pressure power washing with water and a mild detergent to extend the lifecycle to recoating.

Cova-Wall® Cavity System has two Panel options:

OPTION 1: Plain EPS Panel (Virgin Panels)

OPTION 2: Pre-Rendered EPS Panel (Pre-Rendered Panels

are factory coated with polymer modified render and

alkaline resistant fibreglass mesh)

1.Plain EPS Panel System specifications

Plain EPS Panels are used in this system. Panels are fastened and fixed to timber or steel framed buildings having EPS Battens and a Weatherproof Breathable Wall Wrap (Sarking) in between. Starter Channel Beads in required size are fixed on to the bottom frame on top of Wall Wrap. EPS Battens are nailed/screwed onto stud frame leading on to channel; The Panels are installed horizontally and fastened directly into the studs using screws and plastic washers. The Panel joints are then sealed with PU Foam Adhesive, Corner angle beads are fixed and a coat of Patch `Em-Up® is applied. Fibreglass mesh is stuck across the entire Panel surface and The Panels are coated with more Patch `Em-Up® to a thickness not less than 2mm. The Panel is then coated with Fastwall Render® to a thickness between 2 -4mm and finished as per the Cova-Wall® coating system. This consists of two coats of polymeric render (base coat) and one coat of acrylic texture, followed by a coat of decorative top coat sealer having a total minimum coating thickness of 5-6m.

2.Pre-Rendered EPS Panel System specifications

Pre-Rendered EPS Panels are used in this system. Panels are fastened and fixed to timber or steel framed buildings having EPS Battens and a Weatherproof Breathable Wall Wrap (Sarking) in between. Starter Channel Beads in required size are fixed on to the bottom frame on top of Wall Wrap. EPS Battens are nailed/screwed onto stud frame leading on to channel; the Panels are installed horizontally and fastened directly into the studs using screws and plastic washers. The Panel joints are then sealed with PU Foam Adhesive, Corner angle beads are fixed and a 200mm fibreglass mesh is placed over Panel joints only. The Panels are rendered and finished as per the Cova-Wall® Coating System. This consists of two coats of polymeric render (basecoat) and one coat of acrylic texture, followed by a coat of decorative top coat sealer having a total minimum coating thickness of 5-6m.